Automatic burrata production machine

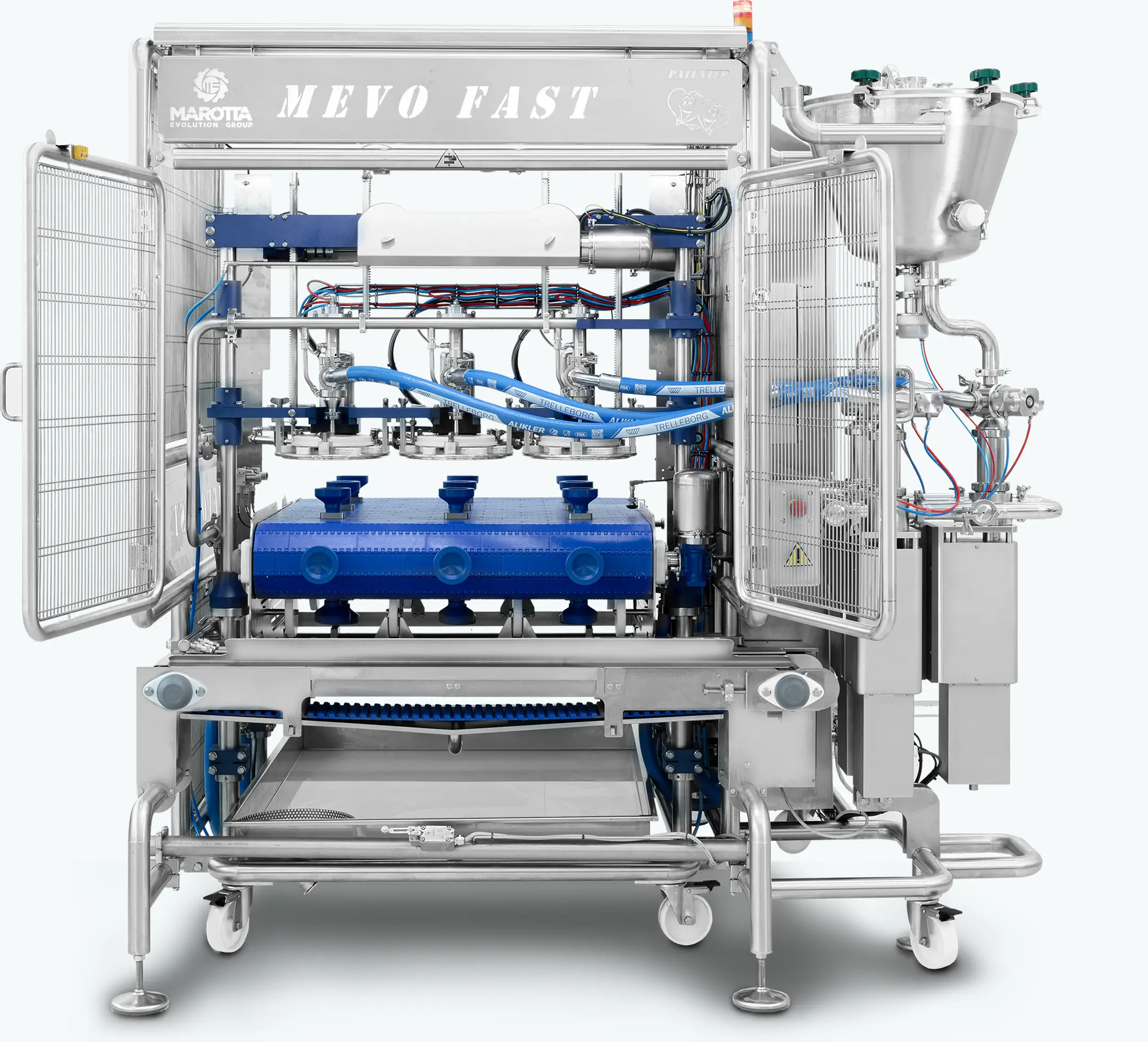

MEVO FAST

The Best-Selling Solution for Automatic Burrata Production

The MEVO FAST is at the forefront of automatic burrata production systems, building upon and enhancing the strengths of previous technologies. It stands out for its compact frame and high productivity, making it the ideal choice for modern dairies.

Efficiency and Versatility for Every Need

This best-selling model is perfect for large-scale burrata production, offering exceptional performance in a small footprint.

- Production Capacity: Up to 1200 burrate per hour.

- Product Flexibility: Produces burrate with and without a head.

- Weight Range: Manufactures burrate weighing from 30g to 400g.

- Operational Simplicity: Enables production without the need for a dedicated expert cheesemaker.

- Advanced Automation: Fully compatible with the MeRobot for automatic and hygienic loading.

“Made in Italy” Quality and Tradition

Like all systems in the Mevo series, the MEVO FAST ensures automatic filling that preserves the quality and traditional authenticity of burrata, fundamental values of Made in Italy.

Automated burrata production

The production process takes place by means of a conveyor belt with special wells, within which the outer shells of mozzarella are deposited, either manually by the operator or automatically with our Me Robot. The belt advances one step to the filling position. Using a patented diaphragm system, the outer shell is lifted from the well and filled by a volumetric dosing unit on board the machine. The filling can be selected by the customer: MEVO FAST can be used, remaining loyal to tradition and filling the mozzarella with the stracciatella, or by trying some gourmet experiments by adding pesto, olives, etc. After the mozzarella shell is filled, this same diaphragm system immediately seals it and then places the finished burrata back in its well. The belt now moves forward another step, depositing the burrata in the basin or the firming cart.

To make the stracciatella filling for burrata Marotta Evolution Group offers its customers the possibility of purchasing the Evotella kneading machine, in order to automate the process of creating the filling. The EVO Transfer (stracciatella filling transfer basin) and the CIP Cart (automatic end of day system cleaning) are also available for purchase.

Advantages of the MEVO FAST burrata production system

One important plus in using the MEVO FAST is that it lowers the risk of contamination, as the product is not filled manually. Especially for the production of burrata with the head, there is no need to use raffia palm or similar systems.

Another important plus is that it makes the product homogeneous, maintaining the traditional form and at the desired finished weight.

Characteristics of MEVO FAST:

Machine type:

1

Time required for format changeover:

– Pneumatic dosing units:

– Electronic dosing units (optional):

15 min.

Width 70 ÷ 80

Height 40 ÷ 50

24 pz.

< 60 dB (A)

700 kg (with pneumatic dosing units)

800 kg (with electronic dosing units (optional))

Color: